Empowering India’s Energy and Economic Security

Designed and developed at its research and development (R&D) centers in California and Ohio, First Solar’s advanced thin film PV modules set industry benchmarks for quality, durability, reliability, design, and environmental performance. Each module features a layer of Cadmium Tellurium (CdTe) semiconductor, derived from byproducts of copper and zinc mining, which is only three percent the thickness of a human hair. In addition, First Solar’s technology does not use crystalline silicon and is not dependent on China’s solar supply chains.

First Solar’s factory in India produces a PV module optimized for the country’s operating environment and needs. The company’s CdTe technology is uniquely advantaged in this market due to its temperature coefficient and spectral response advantages, which can result in 5-8% more energy over its lifetime than crystalline silicon solar panels because of heat and humidity. First Solar has operated in the Indian market for over a decade and has already deployed over 2 GW of its modules in the country.

Building Resilient PV Supply Chains, Driving India’s Renewable Energy Growth.

By investing in India, First Solar is enabling the clean energy self-reliance of a major US ally and strategic partner in the Indo-Pacific. The company’s facility in India helps reduce the country’s reliance on Chinese-made solar panels that may be tainted by the use of forced labor. It also directly enables the Indian government’s efforts to diversify its clean energy supply chain as the country becomes the world’s third-largest electricity consumer while deploying 25 GW of solar each year for the next nine years.

First Solar’s plan to expand its footprint and make its American-designed solar technology in India reflects one of the many ways the two countries can collaborate on tackling climate change, energy security, and the overreliance on adversarial nations for clean energy technologies.

A differentiated manufacturing process.

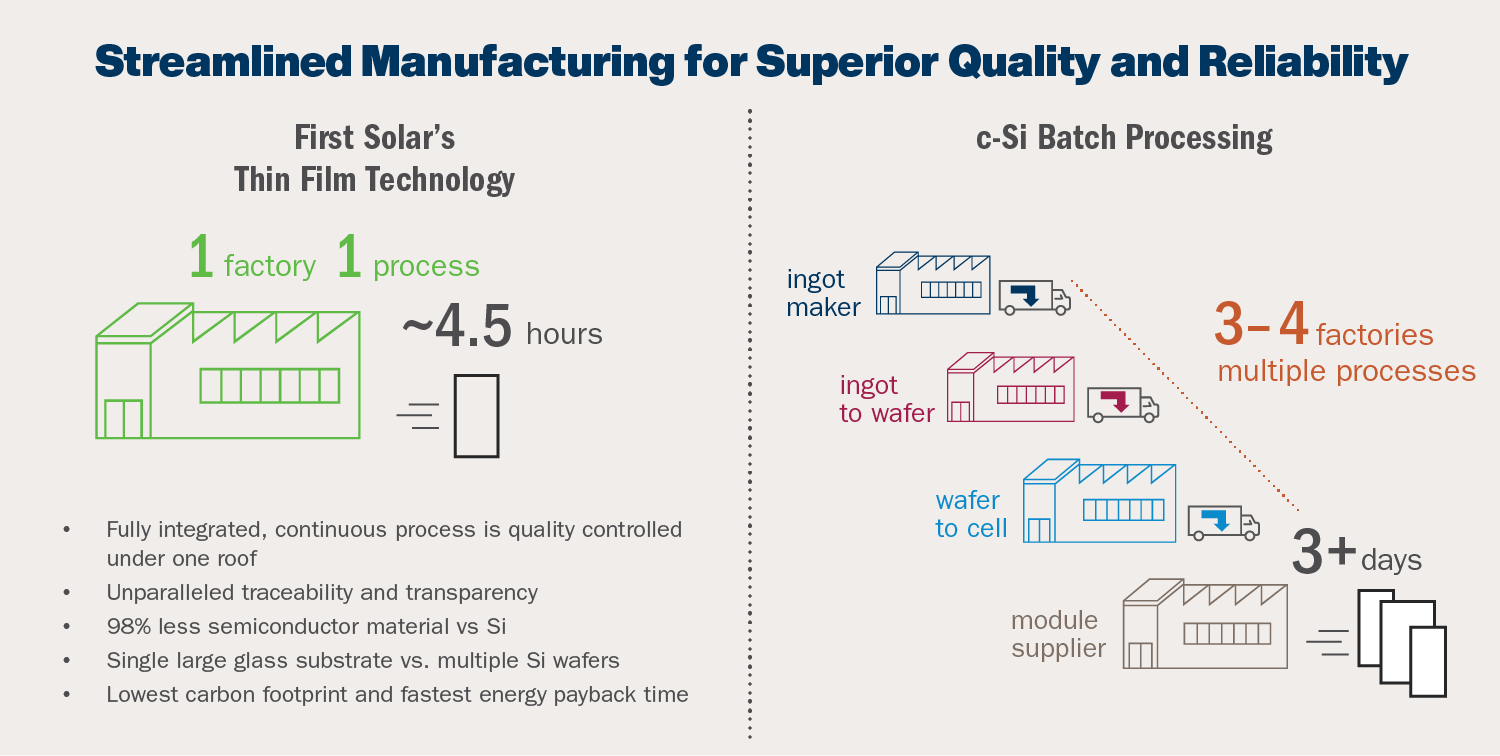

Unlike factories that assemble crystalline silicon panels of the type produced by China, First Solar’s facility will use the company’s proprietary vertically integrated process to transform sheets of glass into fully-functioning solar panels in approximately four hours, all under one roof.

First Solar’s factory in India uses the advanced manufacturing template established for the company’s latest factory in Ohio. It combines highly skilled workers with Industry 4.0 architecture, machine-to-machine communication, artificial intelligence, and Internet of Things connectivity. Since expanding its US footprint in 2019, First Solar has worked to source domestically wherever possible.

First Solar’s manufacturing process uses 98 percent less semiconductor material than traditional crystalline silicon solar panels and yields the lowest carbon footprint and fastest energy payback time in the industry. Every year, First Solar products displace more than 10 times the amount of greenhouse gas emitted through its global operations and supply chain. Learn more about First Solar’s manufacturing process.

Leading the industry with responsible recycling technology.

The facility in India follows First Solar’s Responsible Solar principles across sourcing, manufacturing, and lifecycle management and features an integrated, high-value recycling facility that recovers over 90% of materials from processed modules for reuse. The company’s resource-efficient manufacturing process allows it to produce solar modules with a carbon footprint that is 4-times lower, a water footprint that is four times lower, and an energy payback time that is five times faster than crystalline silicon panels made in China. Learn more about First Solar’s recycling program.

First Solar Manufacturing by the Numbers

3.3 GW DC India annual capacity

~5 secondsRate at which First Solar will produce an

Indian-made solar module

>1,000Expected number of direct employees

~40%Female Workforce

Net-ZeroWater withdrawal manufacturing

in India

90%The amount of semiconductor material and glass

that is recovered in First Solar recycling